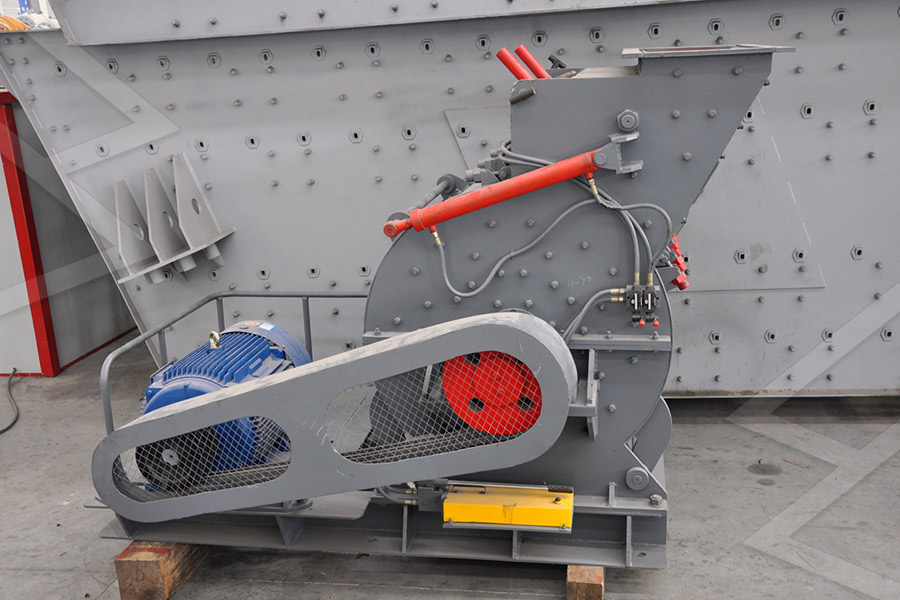

Cement Production Process Raw Material

.jpg)

Manufacturing Process of Cement: StepbyStep Guide

2025年2月4日 Cement production involves multiple steps, from extracting raw materials to fine grinding, heating in kilns, and final packaging Each step ensures that the end product meets There are six main stages of the cement manufacturing process The raw cement ingredients needed for cement production are limestone (calcium), sand and clay (silicon, aluminum, iron), How Cement is Made Cement Manufacturing ProcessDiscover the detailed process of cement production, from raw materials to the final product Learn how cement plays a key role in modern construction and its futureCement Production Process: From Raw Materials to ConstructionUnderstanding the cement production process, from its raw materials to the final product, helps us appreciate the complexities involved in its manufacturing In this post, we’ll break down the The Cement Production Process: Raw Materials, Steps, andCement manufacturers quarry raw materials including limestone, clay, and sand They use fewer resources and contribute to a circular economy by adding raw substances called alternative raw materials, including fly ash, blast furnace How Cement is Made Portland Cement AssociationThe journey of cement production begins with the extraction of raw materials, followed by their meticulous mixing and blending to achieve the perfect chemical composition Subsequent stages include the burning of these processed StepbyStep Guide to the Manufacturing of Cement

.jpg)

Cement Production Demystified: StepbyStep Process and Carbon

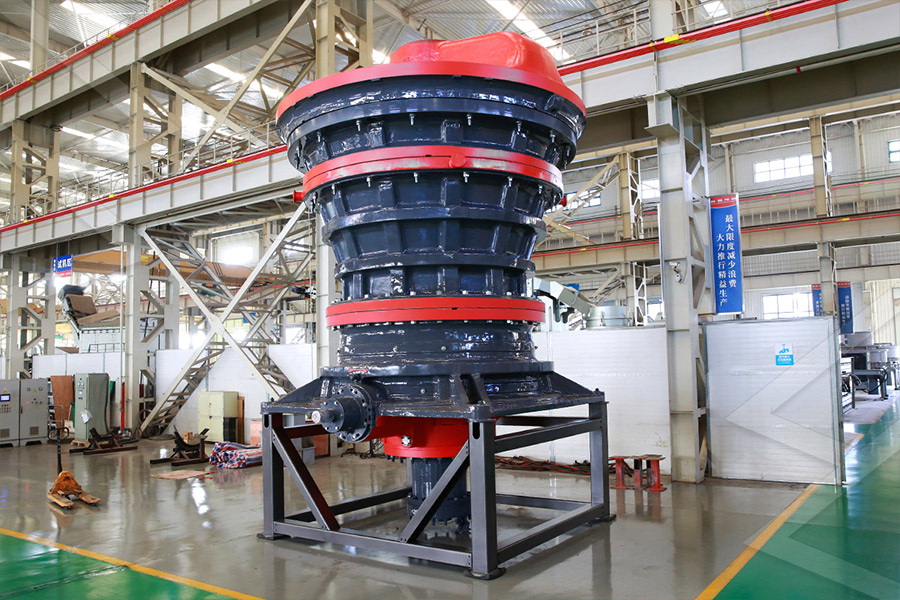

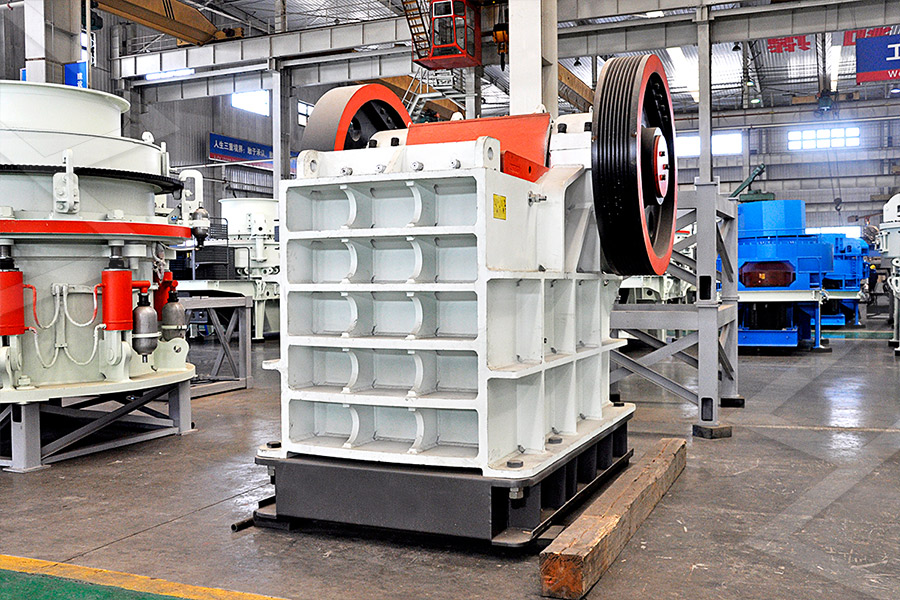

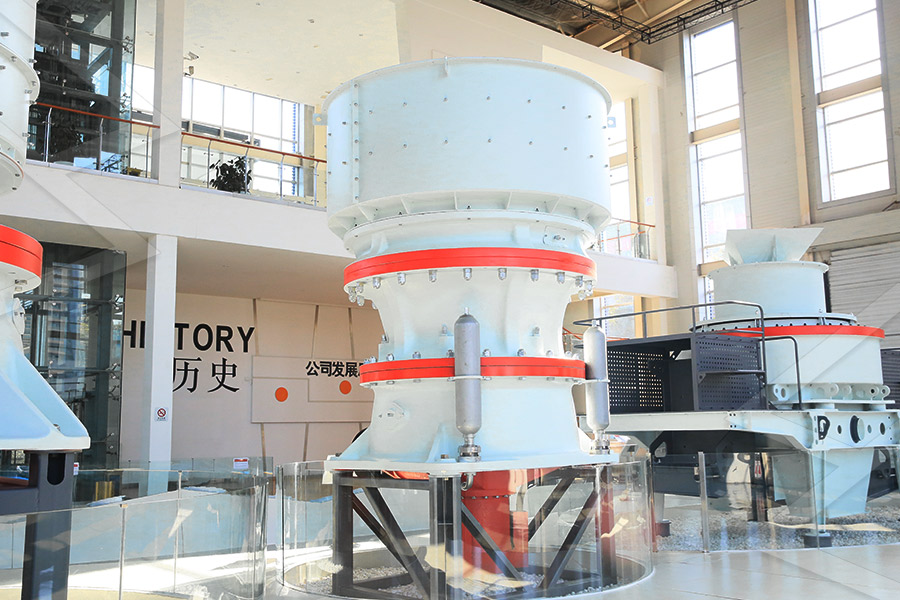

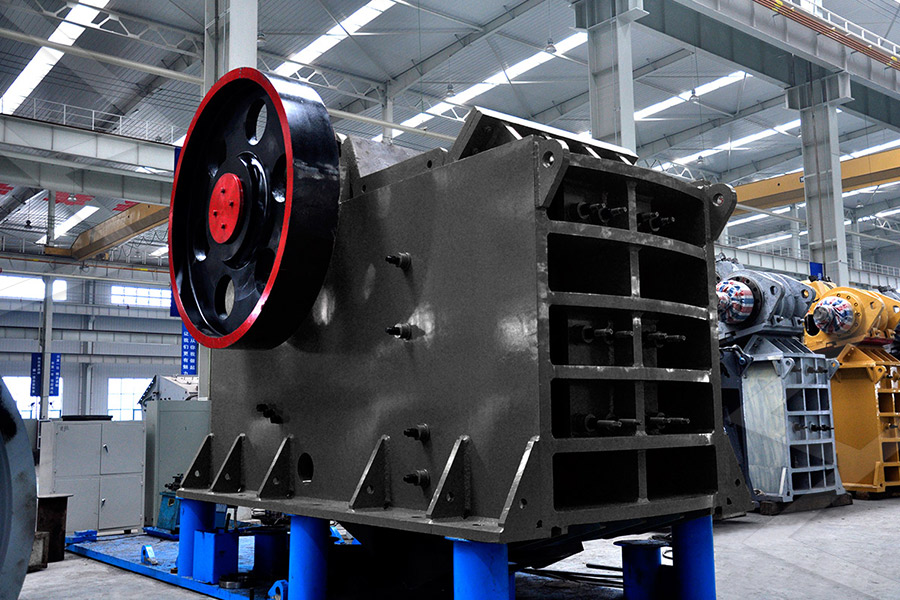

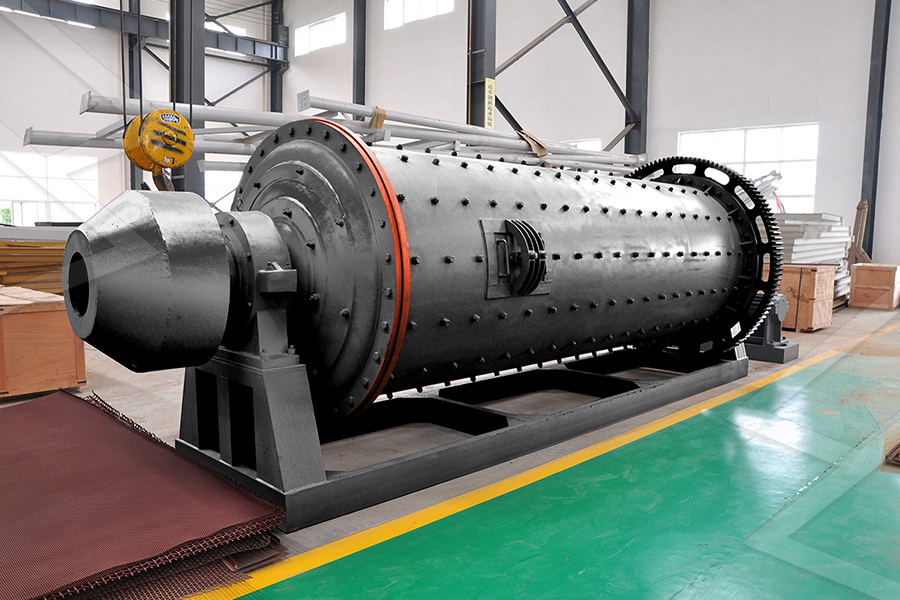

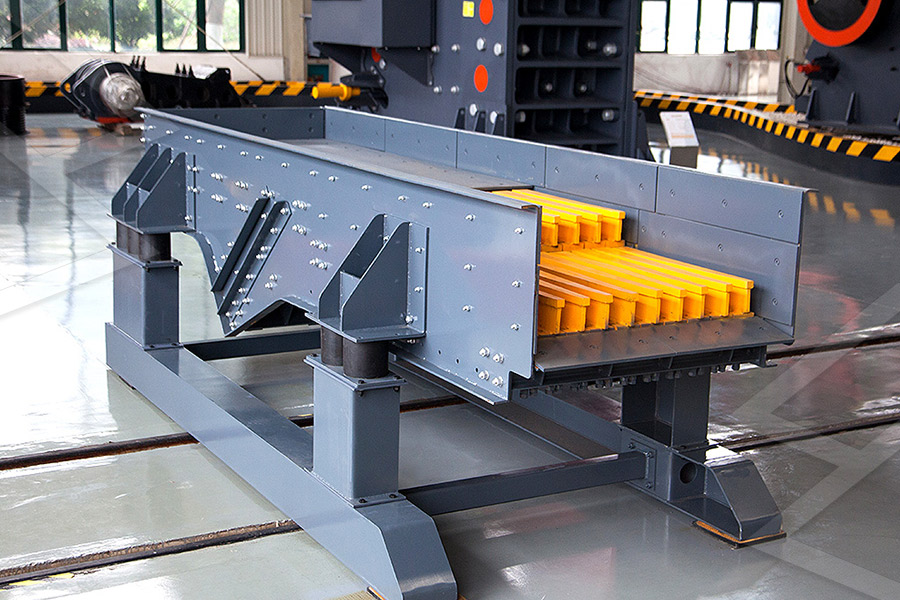

The production of clinker in a kiln is a key process in the production of cement The raw materials used in this process typically include limestone, clay, and sands while other minerals such as 2023年12月20日 Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as The Cement Manufacturing Process Thermo Fisher Cement is foundational to modern construction, underpinning everything from homes to highways Its manufacturing is a complex process that transforms natural raw materials like limestone, clay, and gypsum into a material with StepbyStep Guide to the Manufacturing of CementGenerally, the limestone accounts for 80% of cement raw materials, which is the main cement manufacturing material Minging at a limestone quarry Cement plants are usually built near the quarry of limestone so the quarried limestone How Is Cement Produced in Cement Plants Cement The production of raw cement involves the extraction and procurement of raw materials like limestone and clay or iron ore These materials are then crushed and finely ground to form the raw mix The raw mix is then subjected to hightemperature heating in a kiln, reaching temperatures around 1400°C in a process called clinkerExplore Raw Material Used For Cement Production JK Cementthe most important building materials Whether for houses, bridges or tunnels, we cannot imagine our modern world without it Join us for a short tour to experience how cement is made: starting with the extraction of raw materials and ending with the finishedFrom raw materials to cement

Portland Cement Manufacturing Process

2024年12月25日 Cement is one of the most widely used materials in the construction industry It is the primary ingredient in concrete, which forms the backbone of modern infrastructure The manufacture of cement involves several steps, each contributing to the final product’s strength, durability, and versatility This article outlines the history, materials, and stepbystep 2015年12月9日 Table 1 Raw materials are used to produce the main cement elements (Mohsen, 2015) • Quarry The process of obtaining raw materials for cement manufacturing involves mining and quarrying natural (PDF) Cement Manufacturing ResearchGate2020年9月29日 Introduction Portland cement underpins modern global development As such, it is the most abundantly produced material in the world (Deolalkar Citation 2016)The world has an abundance of the primary raw An overview of alternative raw materials used in The crushed raw materials are then delivered by beltconveyor to our production facilities, where we manufacture cement through a closely controlled chemical process In this process the limestone and clay are first prehomogenized, a process that consists of combining different types of limestone and clayProduction Process CEMEX PhilippinesThe cement manufacturing process starts from the mining of raw materials that are used in cement manufacturing, mainly limestone and clays A limestone quarry is inside the plant area and a clays quarry is as far from the plant area as 25 km The limestone is Manufacturing process Lafarge2024年9月5日 These raw materials are blended in definite quantities to obtain a uniform and homogeneous raw mix which is very crucial in the production of good quality cement The Manufacturing Process of Cement Now, let’s explore the steps involved in the cement production process in more detail:A Comprehensive Guide to the Cement Manufacturing Process

Cement Production an overview ScienceDirect Topics

13222 Energy use in cement production The production of cement is an energyintensive process using primarily fossil fuel sources Cement comprises about 10% of a typical concrete mix but accounts for 92% of its energy demand Cement production requires the pyroprocessing of large quantities of raw materials in large kilns at high and sustained temperatures to produce 2020年9月26日 The manufacturing of cement generally involves four steps: Mixing Burning Grinding Storage Mixing: The mixing of raw materials can be done either with dry process or wet process In dry process the calcareous and argillaceous materials are grinded to the required Cement Manufacturing Process Chemical Engineering World1 天前 The manufacture of Portland cement is a complex process and done in the following steps: grinding the raw materials, mixing them in certain proportions depending upon their purity and composition, and burning them to sintering in a Manufacturing of Portland Cement – Process and MaterialsClinker and cement production is an intensive process in terms of natural raw material and energy input Limestone (primary source of calcium carbonate CaCO 3 ) and clay (primary source of silica SiO 2 , alumina Al 2 O 3 and iron oxide Fe 2 O 3 ) are typically mined in companyowned quarries and preblended to a target chemical material compositionCement Production Process Regain Materials76 4 Cement Manufacturing—Technology, Practice, and Development Fig 42 Modern dry process cement production process 424 Manufacturing of Cement Clinker The prepared raw material is called the “kiln feed” and is fed to the kiln In the kiln, this kiln feedCement Manufacturing—Technology, Practice, and Development2016年1月20日 Natural material deposits are limited, and hence, they will not be able to supplement the largescale production and consumption of cement Raw materials for clinker production are, for good reasons, primarily based on limestone, clay, or its natural mixture, marlAnalysis of material flow and consumption in cement production process

.jpg)

Cement SpringerLink

2021年3月3日 Once the raw materials for cement manufacturing are selected, the next step is to calculate the composition of the raw mix for determining the quantitative proportions of the raw materials, eg, limestone 80% and clay 20% The main objective of this process is The Manufacturing Process The manufacture of concrete is fairly simple First, the cement (usually Portland cement) is prepared Next, the other ingredients—aggregates (such as sand or gravel), admixtures (chemical How concrete is made material, manufacture, 2015年9月15日 Electricity is used in the cement production process for raw materials extraction, blending, grinding, homogenization, clinker production, cement grinding and convey, packing and loading Gu et al (2012) reported that average electrical energy consumption was about 110 kWh/t cement in China's cement industryAnalysis on differences of carbon dioxide emission from cement The Cement Production Process Cement kilns are massive cylindrical structures, lined with refractory brick, into which a limebearing material and fuel such as coal or gas is fed There is a range of different kiln designs but all rely on the same basic processes The Cement Production ProcessSummary of production process Cement is typically made from limestone and clay or shale These raw materials are extracted from the quarry crushed to a very fine powder and then blended in the correct proportions This blended raw material is called the 'raw feed Cement manufacturing components of a cement plant Understanding CementThe paper details the cement manufacturing process, highlighting the different stages involved, including the mixing of raw materials, the heating of the raw mix in rotary kilns to produce clinker, and the subsequent cooling and grinding processes Various THE CEMENT MANUFACTURING PROCESS Academia

.jpg)

Analysis of material flow and consumption in cement production process

2016年1月20日 In the surveyed cement plant, three balances are established between input and output material in the raw mill, clinker production, and cement grinding system 248 t, 469 t, and 341 t of materials are required to produce a ton of the product in raw material24 Turning waste into a source of raw material and fuel 8 25 Feeding points for waste materials into the cement manufacturing process 9 3 Selection of fuels and raw materials 10 31 Considerations for cement manufacturers 10 311 Kiln operation 10 31Guidelines for CoProcessing Fuels and Raw Materials in Cement The cement production process 1 The Quarry: The cement production process begins with the extraction of limestone and clay from the quarry 2 Crusher and PreBlending: The material is then crushed to reduce particle sizes and blended to reduce variability inA practical guide to improving cement manufacturing processes 2023年12月20日 Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as The Cement Manufacturing Process Thermo Fisher Cement is foundational to modern construction, underpinning everything from homes to highways Its manufacturing is a complex process that transforms natural raw materials like limestone, clay, and gypsum into a material with StepbyStep Guide to the Manufacturing of CementGenerally, the limestone accounts for 80% of cement raw materials, which is the main cement manufacturing material Minging at a limestone quarry Cement plants are usually built near the quarry of limestone so the quarried limestone How Is Cement Produced in Cement Plants Cement

.jpg)

Explore Raw Material Used For Cement Production JK Cement

The production of raw cement involves the extraction and procurement of raw materials like limestone and clay or iron ore These materials are then crushed and finely ground to form the raw mix The raw mix is then subjected to hightemperature heating in a kiln, reaching temperatures around 1400°C in a process called clinkerthe most important building materials Whether for houses, bridges or tunnels, we cannot imagine our modern world without it Join us for a short tour to experience how cement is made: starting with the extraction of raw materials and ending with the finishedFrom raw materials to cement2024年12月25日 Cement is one of the most widely used materials in the construction industry It is the primary ingredient in concrete, which forms the backbone of modern infrastructure The manufacture of cement involves several steps, each contributing to the final product’s strength, durability, and versatility This article outlines the history, materials, and stepbystep Portland Cement Manufacturing Process