Ore Ore Ore Grinding Equment

Efficient Iron Ore Processing: A FiveStep Guide

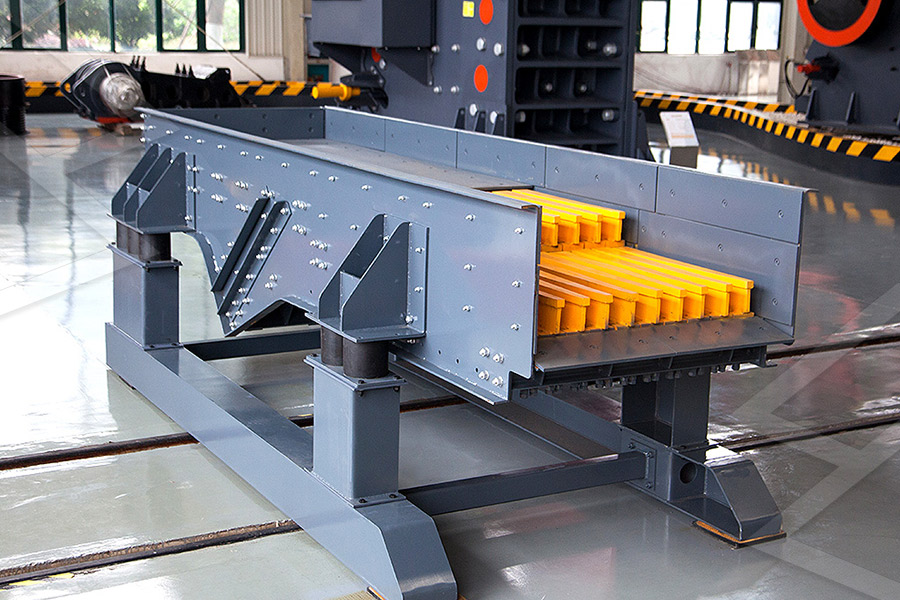

2025年2月22日 The five key steps in iron ore processing include: (1) crushing and grinding, (2) beneficiation (ore separation), (3) pelletizing or sintering, (4) smelting and refining, and (5) casting, rolling, and postprocessingWith features of high wear resistant roller surface, great crushing ratio, higher availability, investment and cost saving and flexible configuration, the HPGR is capable to process various Ore Grinding MillSBM Industrial Technology Group2023年7月20日 According to the material transmission methods, ore grinding is divided into dry grinding, wet grinding, and moist grinding Dry grinding relies on pneumatic conveying, in Ore Grinding SpringerLink2024年8月15日 Mineral processing, also known as ore dressing or mineral beneficiation, typically consists of four key unit operations: comminution, sizing, concentration, and dewatering 1 Comminution involves both crushing and Mineral Processing Plants: What You Need to KnowOre grinding is a process to further reduce and disperse the ore particle size In the mineral processing industry, ore grinding is the particle size preparation before the separation of the Ore Grinding Methods and Process of Ore Grinding2023年6月1日 Measurement and control for ore grinding and classification is the process of detecting and controlling the key equipment and key parameters in grinding and classification Measurement and Control for Ore Grinding and Classification

.jpg)

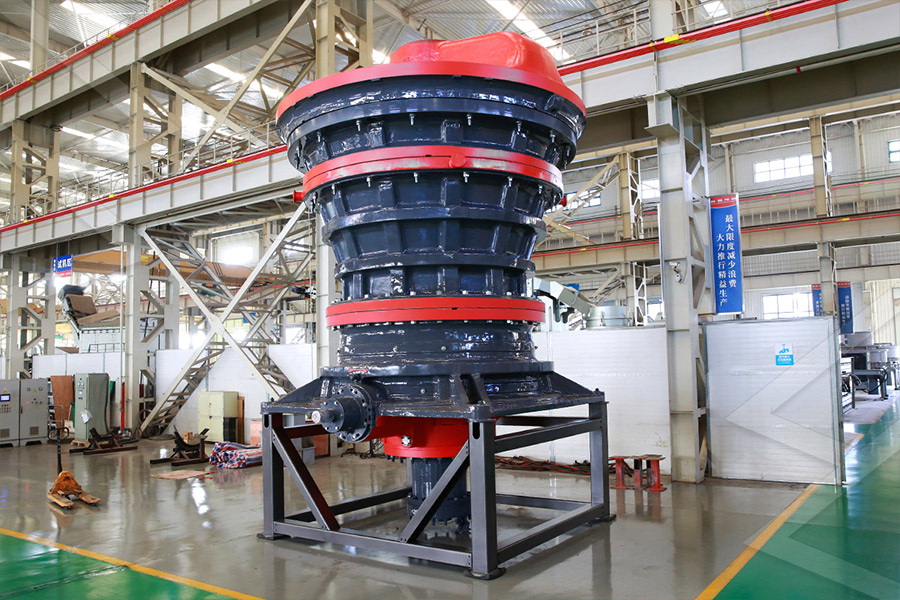

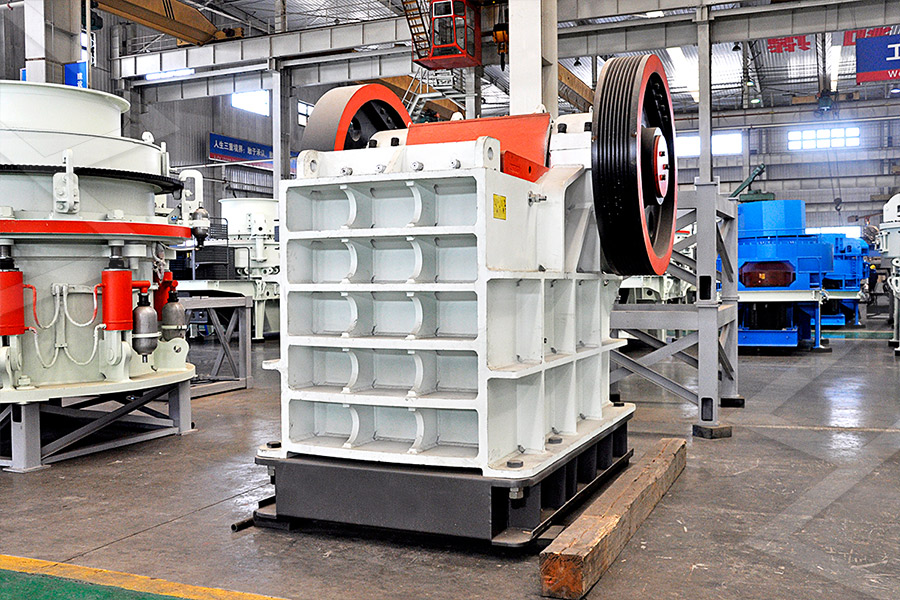

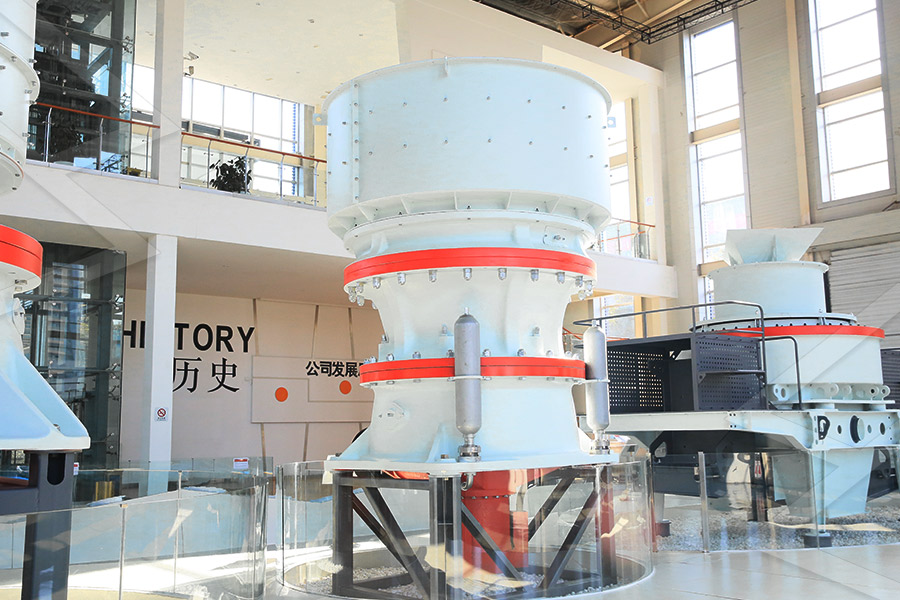

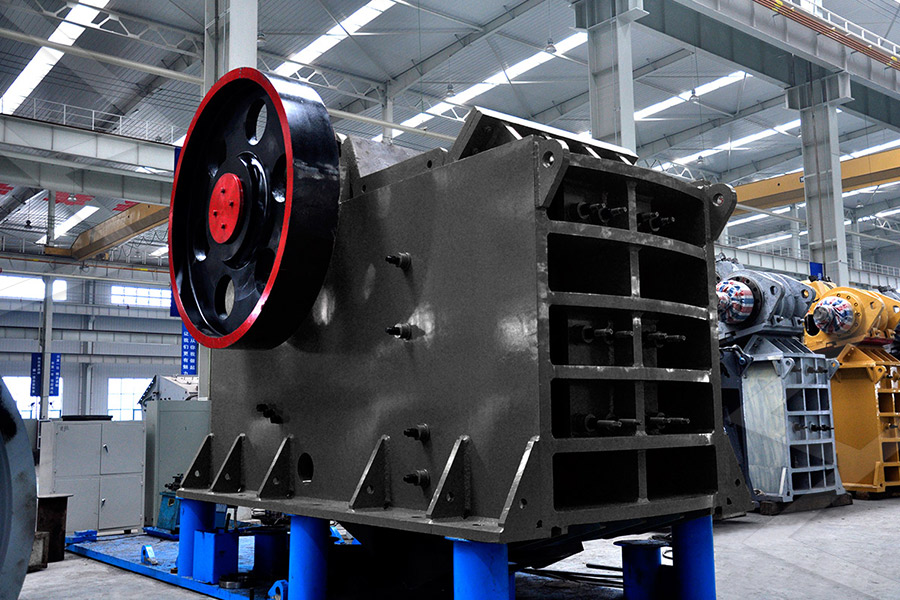

How to Choose the Right Crushing and Grinding Equipment for

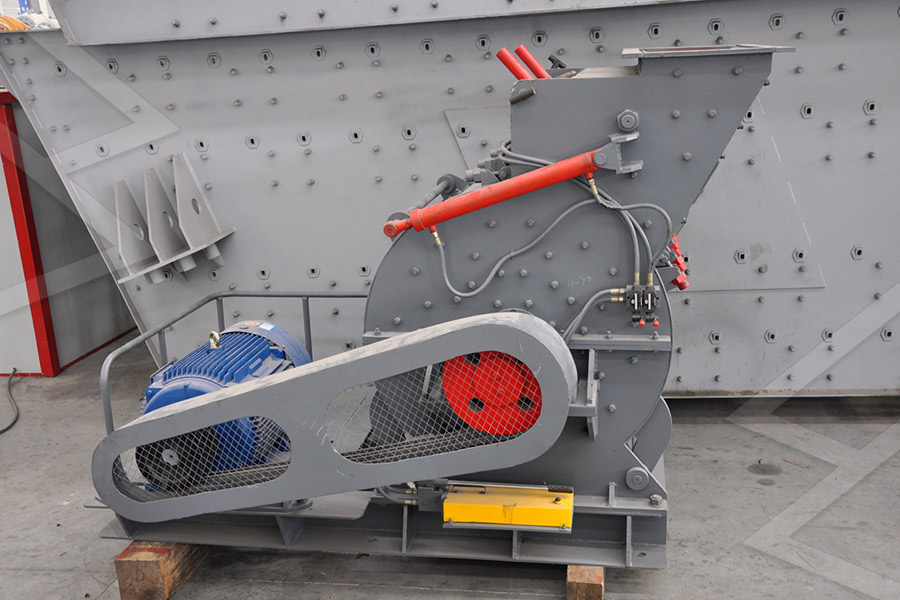

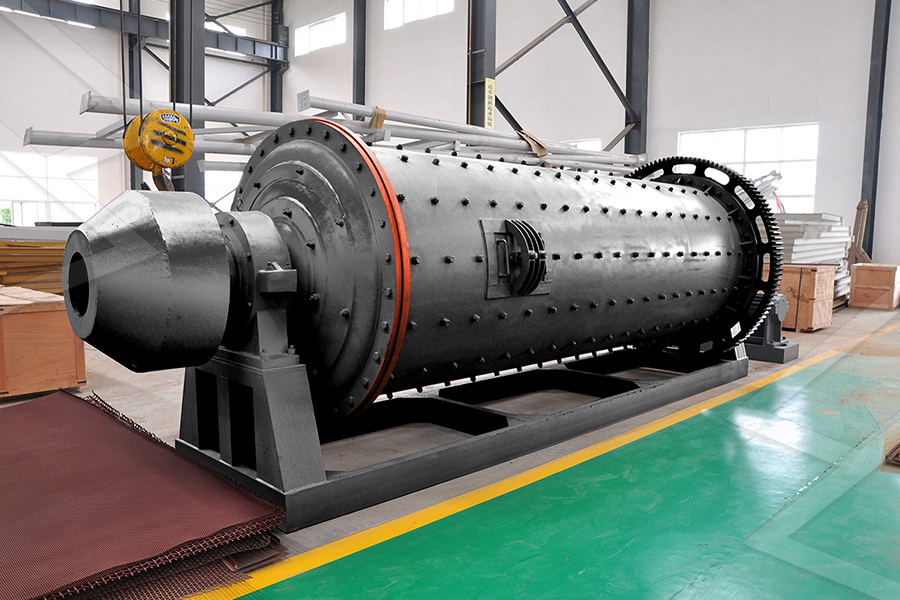

2024年10月12日 Choosing the right crushing and grinding equipment for metal ore processing involves understanding the characteristics of the ore, production requirements, and Efficient Grinding: Advanced grinding technology ensures efficient material reduction, enhancing productivity Adjustable Particle Size: By modifying the steel ball ratio and grinding duration, the discharge particle size can be easily Ore Grinding Ball Mill ZONEDINGOre crushing and screening, grinding and classification are essential preparatory work before separation to get proper ore size There is a balance to keep proper ore size neither too rough (insufficient liberalization) and too fine (overcrushed) in order to achieve high Ore Crushing and GrindingOre Beneficiation Metalcess2025年4月10日 When secondary grinding is required, a wet overflow ball mill can be selected as the grinding equipment at this stage Grid type ball mill Its advantage is that the ore discharge speed is fast, it can reduce the over Ball Mill Is The Key To Grinding Lithium Ore JXSC Jaw Crushers Concentrating table Cone Mills Jigs testers Over 5 decades, MINERAL PROCESS EQUIPMENT PVT LTD, has evolved as a progressive manufacturing company, adding value to the mines mineral processing Mineral Process Equipment India Pvt Ltd, Mumbai, IndiaWet Grinding Mills is mainly used for separation of gold, silver, lead, zinc, molybdenum, iron 3After adding into ore,the materials are under the extrusion of grinding roller weight to revoluting and rotating with runner wheels,when twisting that coming into being Wet Grinding Mill ore processing

Ore Treatment an overview ScienceDirect Topics

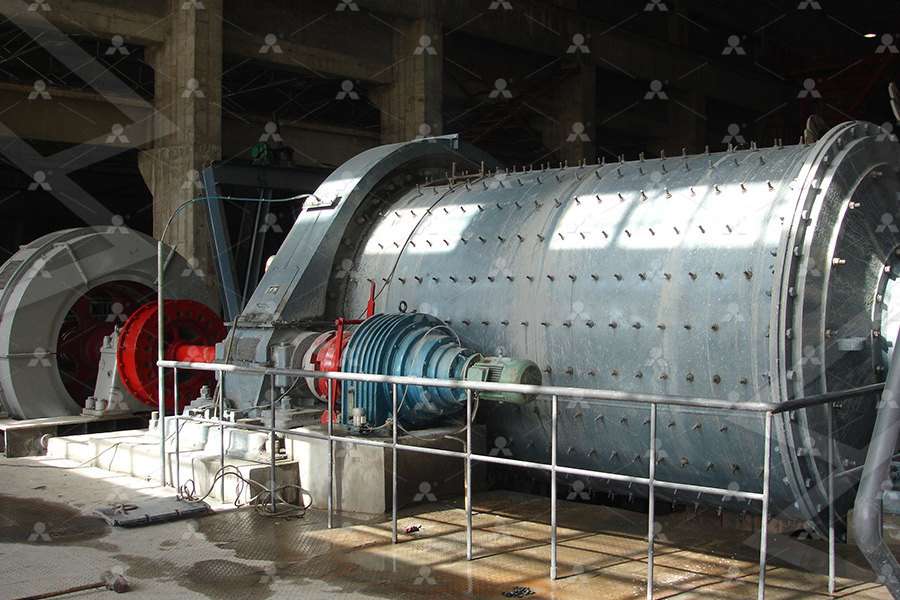

21 Introduction Ore handling is a key function in mining and mineral processing, which may account for 30–60% of the total delivered price of raw materials It covers the processes of transportation, storage, feeding, and washing of the ore en route to, or during, the various stages of treatment in the mill 2013年4月1日 mills, which use both ore and steel balls as grinding media (Wei and Craig, 2009b) In the case of a ball mill the ore is crushed before it enters the mill, whereas a SAG mill receives runofmine (ROM) ore directly (Stanley, 1987) A SAG mill in a single Analysis and validation of a runofmine ore grinding mill circuit Ball mills have been the primary piece of machinery in traditional hard rock grinding circuits for 100+ years They are proven workhorses, Sold individually or as part of our turnkey ore processing system For questions and/or an expert opinion on what size we Ball Mills Mt Baker Mining and Metals2023年4月27日 Iron ore is one of the most abundant resources in the world and is used to produce various products such as steel The process of crushing, grinding, and processing iron ore is an important step in producing steel, as it allows for the extraction of the iron from the oreIron ore crushing, grinding, processing – Mining Equipment 2024年1月1日 Grinding operation quality indices mainly include four aspects (1) Grinding fineness, which is the percentage of the ore particles less than pecified size after being grounded and discharged (2) Mill operation rate, which is the percentage of the actual working time of Ore Grinding SpringerLink2024年6月28日 Glowy Ore (Purple): Home Village Star Bonus, Clan Wars, the Trader, and the ingame Shop Starry Ore (Gold): Clan Wars, the Trader, and the ingame Shop Now that you know how you can get Ores, get out there, earn them, and upgrade your Hero For more Clash Of Clans Ores: Best Way Get This Resource To

.jpg)

Iron ore crusherIron Ore crushing plantIron ore processing

In iron ore concentrator, ball mill and regrinding ball mill is used to grind iron ore into fine powder Hammer crushers are widely used in small iron ore mine with small capacities That's because in such situation, the cost and the difficulty of changing and However Stedman impact crushers, mills, and grinders are used in nearly every mineral, ore, and mining applicationWhether you are processing iron ore, coal, rock, salt, wood chips, or clay – to name a few – we have your solution to size reduction Industrial Ore, Mineral, Slag Crusher Stedman 2016年7月8日 * Crushing provides for two 7hour shifts, eighth and sixteenth hours are for cleanup Rod and Ball Milling each provide for three 8hour shifts of continuous operation By referring to equipment manufacturer’s bulletin on Equipment Sizing: Crusher or Grinding Mill2025年2月22日 Iron ore is the primary raw material for steel production and one of the most essential minerals in the global economy As the demand for highgrade iron ore increases, efficient processing methods become crucial This guide explores the key steps in iron ore processing, from extraction to pelletizing, and highlights the essential equipment used at each Efficient Iron Ore Processing: A FiveStep Guide2009年1月1日 Hematitedominated ore types had significantly higher P 80 values after the primary grinding step A compared to the other ore types Generally, Fe content increased in finer particle size classes Processing of Magnetite Iron Ores–Comparing Grinding Options2023年7月30日 3 Select grinding equipment: – For onestage grinding, overflow type ball mill can be selected – For twostage grinding, choose latticetype ball mill for the first stage and overflowtype ball mill for the second stage – According to the daily processing capacity of the How to choose lead zinc ore grinding process and grinding

.jpg)

Mechanism Ore processing Help : r/feedthebeast Reddit

So I'm working on a Mekanism 5x ore processing setup and, as per usual, the chemical crystallizer is the bottleneck (even when fully upgraded) To have the crystallizer not bottleneck you need 10 of them to 1 of the each of the other machines in the system Each Rotational speed: 700 rpm 1,500 rpm The Vibratory Disc Mill RS 200 is engineered for size reduction, mixing, grinding of mediumhard, frail or course materials to analytical quality Rotational speed: 912 rpm simultaneously This mill accepts grinding set weights of up to 30 kg, the largest grinding jar has a volume of 2,000 ml Ore mill, Ore grinding mill All industrial manufacturers2015年3月15日 The application of verticalrollermills (VRM’s) for ore grinding is part of the second strategy The grinding parts of a Loesche mill (Fig 1) are a rotating table (1) with a horizontal grinding track and rollers (2), which are pressed onto the table by lever arms and a Research of iron ore grinding in a verticalrollermill2025年4月10日 A single sulfide ore is usually treated by flotation process, using crushinggrindingclassificationflotationconcentration process to select a single copper sulfide ore as copper concentrateCopper ore beneficiation process The principle of priority flotation process is: crushing and screening→grinding and classification→priority flotation of copper Copper Ore Processing Plants, Flow And Equipment2023年7月22日 Ore crushing is the process of breaking, splitting, extrusion, impacting, and grinding of large solid ore with external force to reduce the particle size of large ore materials Ore crushing provides suitable particle size of material for subsequent ore grinding, beneficiation or smelting, which is the preparation process before beneficiation or smeltingOre Crushing SpringerLinkBauxite processing equipment As we know, bauxite ore is very hard, so it takes a longer time for crushing In the bauxite processing, the Jaw Crusher is used in the coarse crushing, and Impact Crusher is used in the secondary, Cone Crusher is in fine crushingBauxite processing plant, bauxite ore crushing and ore grinding

.jpg)

Find A Wholesale tin ore processing machine Online

Gold Ore Jigging Machine Separation Process Tin Ore Large Particle Beneficiation Machine LeadZinc Ore Jigging Gravity Machine $4,399004,59900 Min Order: 1 setNow chatting: leawaysschool/solutionhtmlContact Us: leawaysschoolIron Ore Mining EquipmentIron ore processing plant is generalIron ore mining grinding equipment YouTubeAutogenous mills operate without grinding bodies; instead, the coarser part of the ore simply grinds itself and the smaller fractions To semiautogenous mills (which have become widespread), 5 to 10 percent grinding bodies (usually metal spheres) are addedMineral processing Metallurgy, Crushing Grinding BritannicaOre sorting in mineral processing is separating the ore according to their size subsequent to the crushing and grinding of ore For ore sorting in mineral processing, there are several methods Depending on the mineral being processed, some may require more than one method before being determined ready for the next ore beneficiation processOre Processing Multotec2023年7月9日 OUT OF ORE TUTORIAL CONVEYOR MININGSubscribe for more: https://youtube/@splitintwogaming?subconfirmation=1In HOW TO CONVEYOR MINING METHOD OUT OF ORE2015年1月1日 Ball mills( Iron Ore grinding system) 2X 50 TPH (ii) Vacuum Disk Filter 4X 50 TPH (iii) Coal Grinding System 1X 5 TPH (iv) flux and coke grinding System 1X 5 TPH (v) Mixer 1X100 TPH (vi) Balling Disc 3X 75 TPH (vii) Travel Grate 1X 80 TPH (viii Pollution Iron Ore Pelletization Technology and its Environmental Impact

Iron Ore Beneficiation Plant Equipment For Mining Process

2023年9月4日 Iron ore is an essential ironmaking material with a wide application The iron ore processing plant usually adopts the magnetic separation method The iron ore magnetic separation production line consists of iron ore beneficiation equipment, including crushing equipment, screening equipment, grinding and grading equipment, magnetic separation 2023年7月1日 For a Merensky Reef ore, dry grinding ended up in more stable highly loaded froths, faster flotation kinetics and lower flotation selectivity [12] In a more recent study, Liu etal [13] tested the impact of the grinding environment on two coppersulfide ores and In On the impact of grinding conditions in the flotation of semi Ore crushing and screening, grinding and classification are essential preparatory work before separation to get proper ore size There is a balance to keep proper ore size neither too rough (insufficient liberalization) and too fine (overcrushed) in order to achieve high Ore Crushing and GrindingOre Beneficiation Metalcess2025年4月10日 When secondary grinding is required, a wet overflow ball mill can be selected as the grinding equipment at this stage Grid type ball mill Its advantage is that the ore discharge speed is fast, it can reduce the over Ball Mill Is The Key To Grinding Lithium Ore JXSC Jaw Crushers Concentrating table Cone Mills Jigs testers Over 5 decades, MINERAL PROCESS EQUIPMENT PVT LTD, has evolved as a progressive manufacturing company, adding value to the mines mineral processing Mineral Process Equipment India Pvt Ltd, Mumbai, IndiaWet Grinding Mills is mainly used for separation of gold, silver, lead, zinc, molybdenum, iron 3After adding into ore,the materials are under the extrusion of grinding roller weight to revoluting and rotating with runner wheels,when twisting that coming into being Wet Grinding Mill ore processing

.jpg)

Ore Treatment an overview ScienceDirect Topics

21 Introduction Ore handling is a key function in mining and mineral processing, which may account for 30–60% of the total delivered price of raw materials It covers the processes of transportation, storage, feeding, and washing of the ore en route to, or during, the various stages of treatment in the mill 2013年4月1日 mills, which use both ore and steel balls as grinding media (Wei and Craig, 2009b) In the case of a ball mill the ore is crushed before it enters the mill, whereas a SAG mill receives runofmine (ROM) ore directly (Stanley, 1987) A SAG mill in a single Analysis and validation of a runofmine ore grinding mill circuit Ball mills have been the primary piece of machinery in traditional hard rock grinding circuits for 100+ years They are proven workhorses, Sold individually or as part of our turnkey ore processing system For questions and/or an expert opinion on what size we Ball Mills Mt Baker Mining and Metals2023年4月27日 Iron ore is one of the most abundant resources in the world and is used to produce various products such as steel The process of crushing, grinding, and processing iron ore is an important step in producing steel, as it allows for the extraction of the iron from the oreIron ore crushing, grinding, processing – Mining Equipment 2024年1月1日 Grinding operation quality indices mainly include four aspects (1) Grinding fineness, which is the percentage of the ore particles less than pecified size after being grounded and discharged (2) Mill operation rate, which is the percentage of the actual working time of Ore Grinding SpringerLink2024年6月28日 Glowy Ore (Purple): Home Village Star Bonus, Clan Wars, the Trader, and the ingame Shop Starry Ore (Gold): Clan Wars, the Trader, and the ingame Shop Now that you know how you can get Ores, get out there, earn them, and upgrade your Hero For more Clash Of Clans Ores: Best Way Get This Resource To